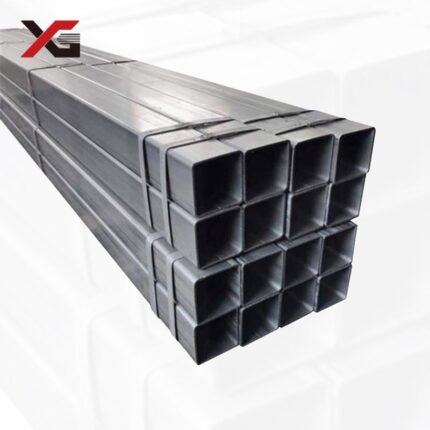

Carbon steel square welded pipe

Carbon steel pipes are pipes made of carbon steel. They are one of the most commonly used metal materials and have good mechanical properties, processing properties and corrosion resistance. According to the production method, it can be divided into two types: seamless steel pipe and welded steel pipe.

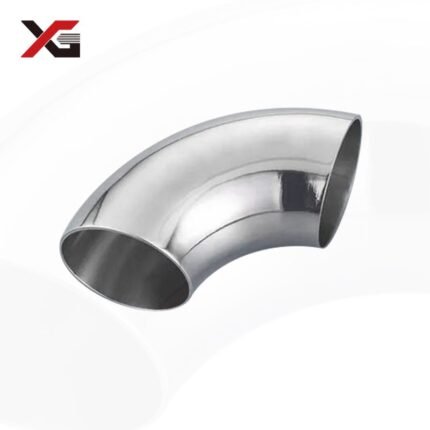

Elbow

Pipe fittings that change the direction of the pipeline The main difference between stainless steel elbows and carbon steel elbows is the material. The chemical composition contained in them will keep the surface of the elbow from rusting and corroding for a long time. In the pipeline system, elbows are pipe fittings that change the direction of the pipeline. According to the angle, there are three most commonly used ones: 45°, 90°, and 180°. In addition, according to the needs of the project, there are also other abnormal angle elbows such as 60°.

Flange

Stainless steel flange is a common component for connecting pipes, which is widely used in chemical, petroleum, pharmaceutical, food and other fields. It can connect two pipes and play a sealing role. Stainless steel flange has the characteristics of simple construction, easy use and reliable sealing, so it is widely used in various industrial fields.

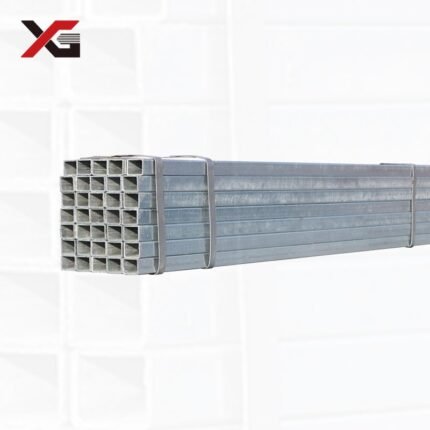

Galvanized round seamless pipe

Galvanized pipe, also known as galvanized steel pipe, is a pipe product that is coated with a layer of metallic zinc on the surface of ordinary steel pipes. The main purpose of galvanized pipe is to prevent corrosion and rust, thereby extending the service life of the steel pipe. Galvanized pipes are divided into two types: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing has a thicker, uniform coating and strong adhesion, while electro-galvanizing has a lower cost and a smoother surface.

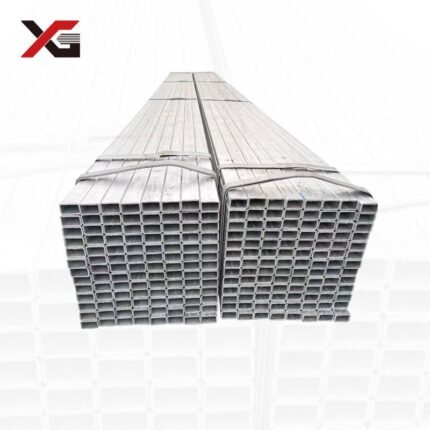

Galvanized square welded pipe

Galvanized pipe, also known as galvanized steel pipe, is a pipe product that is coated with a layer of metallic zinc on the surface of ordinary steel pipes. The main purpose of galvanized pipe is to prevent corrosion and rust, thereby extending the service life of the steel pipe. Galvanized pipes are divided into two types: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing has a thicker, uniform coating and strong adhesion, while electro-galvanizing has a lower cost and a smoother surface.

Ship plate

Carbon steel plate is a rectangular plate made of non-alloy material mainly composed of iron and carbon. In addition to carbon, it also contains a small amount of silicon, manganese, sulfur, phosphorus and other elements. The higher the carbon content, the better the hardness and the better the strength. Due to its good mechanical properties and plasticity, it is widely used in various fields.

Stainless steel coil

Stainless steel is initially produced in slabs, which are then put through a conversion process using a Z mill, which converts the slab into coil prior to further rolling. These wide coils are typically made at around 1250mm (sometimes a little wider) and are known as 'mill edge coils'. After the stainless steel roll is rolled flat, it becomes a stainless steel sheet(plate).

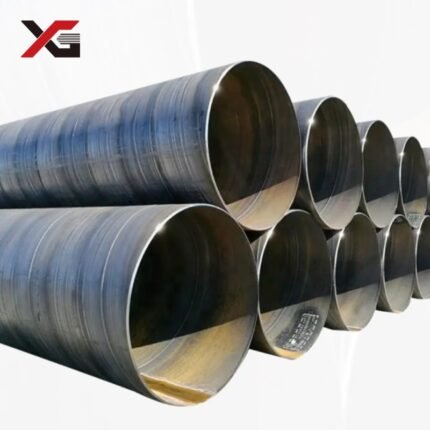

Spiral welded pipe

Spiral welded pipe: It is made by rolling low-carbon carbon structural steel or low-alloy structural steel strips into pipe blanks at a certain spiral angle (called forming angle), and then welding the pipe seams. It can be made of narrower pipes. Strip steel produces large diameter steel pipes. Its specifications are expressed as outer diameter * wall thickness. The welded pipe should ensure that the hydraulic pressure test, tensile strength and cold bending performance of the weld meet the regulations.